Description

The machine is equipped with a workpiece feed by industrial servomotor (servomotor with planetary gear) with a new control system. The servomo-tor and ball screw ensure high speed and maximum accuracy of workpiece feed, even in multiple feed when cutting long pieces. Options of setting three feed rates – 27, 42 or 50 mm/s acording to weight and length of the workpiece to be cut. Maximum length of a single feed is 600 mm.

Central control panel with a big colour touch screen (7.5”) ensures simple intuitive control of alla features of the machine. The control unit allows for programming of up to 60 programmes for quick setting of the feed length in repetitive production. Each programme can be annotated, e.g. by the drawing number. Possibility of programming and cutting of different number of pieces of different sizes without the need for further operation of the machine. The machine can be controlled in fully automatic, semi-automatic or manual mode. In manual mode all functions of the machine are controlled separately.

Due to very cutting of very heavy workpieces the loading floor is equipped with a robust rollers along its entire length, allowing easy motion of the material. Optimum clamping of the workpiece when cutting is facilitated by a full-stroke double-jaw vice which clamps the material both before and behind the cut. The vice moves along linear guides. The moving guide block is adjusted together with the vice jaw. That means that it is always automatically closest to the cut, which contributes to cutting accuracy and speed. Saw band guide block holder also moves along the linear guides. Extremely robust feeding full-lifting vice moves again along the linear guides. For maximum performance the servomotor with ball screw is additionally equipped with cutting-edge planetary gear, which guarantees easy motion of even the heaviest materials. For the expected cutting of very heavy and often uneven materials, e.g. forgings, the vice is equipped with a system gaping simultaneously both jaws. The fixed jaw pushes aside by 15 mm from the material, the movable jaw with full-lifting hydraulic cylinder pushes during the automatic operation also by 15 mm. Thuerefore there is not any conflict between the feed vise and material, and also the accuracy of the feed is ensured. The machine is equipped with a high-performance industrial hydraulic unit. Horizontal and possibly vertical clamping of the material and motion of the sawblade arm to the cut and back into the required position according to the diameter of the material are also hydraulically operated. Hydraulic unit allows you to set the required pressure of the vice.

Both saw band guiding heads are fitted with automatic regulation of feed into cut, which significantly increases the rate and accuracy of cutting and service life of the saw band. Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw band speed by a frequency converter in the range between 15 and 90 m/min., which significantly contributes to cutting accuracy and service life of saw bands. Large base and overall massive framework guarantee exceptional stability of the machine even when cutting heavy workpieces. By default the machine is equipped with a screw conveyor. Its location right below the cut ensures optimum removal of chips. Chips are driven into a metal container with a removable drip tray. The container is a part of the machine base, it is equipped with wheels and simply retractable. High-quality lighting of the work area by a line of powerful LEDs with a cover. Behind the cut the vice can be fitted with a supporting roller for cutting long pieces or a slide of material for short pieces.

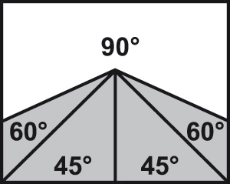

- In order to achieve maximum accuracy and productivity the machine is designed only for upright cutting.

- Very robust machine construction composes of massive castings from grey cast iron and ensures safe vibration absorption.

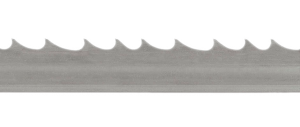

- Large diameter running wheels and precise three-side hardmetal guiding ensure long service life of the band and cutting accuracy.

- Easy intuitive controls by ergonomically places controls on the control panel.

- Overdesign of running wheel bearings, tensioning wheel system and all rotary parts ensures long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an industrial electric motor with worm gearbox.

- The machine is connected to a complete cooling system with a highperformance pump and possibility of regulating the flow on both guiding heads independently and on two additional adjustable outlets. Coolant tank with a high-performance pump is placed in the base of the machine.

- The machine checks correct tension or break of the saw band. If the saw band breaks the machine automatically switches off.